Industrial alarm management focuses primarily on plant safety and accurate process management to optimize productivity. An undesirable trip in the process may lead to a loss of the product , a compromise in product quality as well as a loss of time and money. As the role of maintenance engineers is to maintain their plants at their best efficiency, therefore it is in their interests to mitigate these undesirable trips.

As per ISA 18.2, an alarm can be defined as an audible or a visual means of indicating an equipment malfunction,process deviation or other abnormal conditions to the operator.

Alarms can be classified as follows:

- Process Control Alarms

- System-related Alarms

- Environmental Alarms

- Fire and Safety Alarms

While these alarms are inevitable, the Process Control Alarms are the most frequently triggered, which in turn will have a direct impact on the running process. So an effective alarm management philosophy is required.

Many process industries do not have a defined master alarm database. Without a defined alarm philosophy, your control system will not be able to take control over the process. Since humans can only pay attention to a limited number of processes at a time, it must be ensured that the alarms are presented at a rate which can be assimilated by a human operator, particularly when the plant is upset. Hence,the alarm system should be designed keeping the limitations of humans in mind.

Large process industries which use a DCS-based control system will have a master alarm database and an alarm philosophy. However these are provided by the consultant or licenser. Which alarms are important? An alarm response is not just a function of the specific process being controlled,it is a human–machine interaction between the console engineer and the control system. So the emotions of the operator and his concentration are the prime factors in determining the control process

|

Protection Layer |

Probablity of Failure (IEC 61511/ISA-84) |

| Operator response to alarms | 10% |

| Human performance (trained, no stress) | 1.0% to .01% |

| Human performance(under stress) | 50% to 100% |

Alarm floods and nuisance alarms will adversely affect your operator’s mental state. A good operation is the result of an operator’s situational awareness, his knowledge about the current state of the process and his predictions about the future of the process. An alarm system will function at its full capacity when the operator is aware about the reason, nature, criticality and importance of each alarm in the alarm database.

Here comes the role of alarm rationalisation. Firstly, your alarm database must be accurate. Alarm floods and unnecessary alarms greatly hinder the effective response of the operator by affecting their ability to address critical alarms. When alarms trigger at 10 alarms per minute ,the operator may just acknowledge them and it remains as a change in colour in your alarm list. Hence Alarm Management becomes pointless.

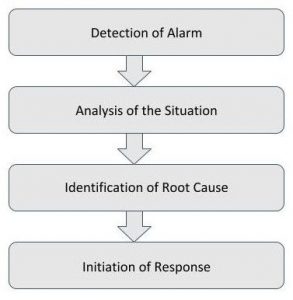

Each alarm must be analysed and a real time corrective action must be implemented in the process variable to restore your process to normal operating conditions. Alarm rationalisation is mandatory for the safety of the plant. Rationalisation is a continuous process where the potential alarms are reviewed and documented. This process is to avoid alarm overloads by eliminating nuisance alarm and refining alarm responses. For a new system, it can be implemented during the comprehensive engineering design phase. For a running plant it can be done during the operation and maintenance phase. Alarm Tsunami after an upset is a major issue which affects the operator’s action as it confuses the operator in prioritizing the alarms Every alarm in the system must be reviewed according to your process design, control philosophy and operator feedback. If if it is not relevant, then remove it from your alarm list. It is very important to document the reason for the alarm, the consequences if the alarm is ignored and the maximum response time required to avoid such consequences.

Rationalising an Alarm:

The following things should be done to rationalise an alarm:

- Eliminate system related alarms from the process alarm database. The system redundancy alarms, card integrity alarms are to be taken care by your Instrumentation Engineer.

- For an expected event which requires an operator action, only a prompt alarm is required.For example, if your Suction Pressure goes low, then definitely the Discharge Flow will be minimum. So the Low Flow alarm can be replaced by a prompt.

- An event which does not require an immediate operator response can be replaced with an operator message.

- Alarm prioritization in DCS – Alarm prioritization is defined as the relative importance assigned to an alarm to indicate the urgency of response. The alarm is prioritized based on severity of the consequence (eg. Personal safety, equipment damage, environmental and economic loss) and the available time to take corrective action.

- Alarm suppression and alarm shelving is performed to avoid alarm flooding. It is done by the Instrumentation team by carrying out calibrations and inspections of loops.

- Conditional alarm interlocks are implemented to avoid alarms during start up and shut down.

The following validations are to be done during the alarm rationalization:

- Does it indicate a malfunction/deviation/abnormal condition ?

- Does it requires a timely operator response ?

- Is it a unique alarm ?

- Is it the best indication of the root cause of the abnormal situation?

Benefits of alarm rationalization

- The operator can effectively control the process instead of just acknowledging the alarm.

- Fewer product loss by avoiding the process trip.

- Operator stress is reduced

This article was written by Adarsh PL, Solution Architect at CONSYST Technologies.

Are you fed up with your Alarms? Let us help you.