End User:

Ministry of Environment, Water, and Agriculture (MoEWA), Saudi Arabia

Scope:

Design, Supply, Installation, and Commissioning of Central SCADA System for water treatment plants, Sewage treatment plants, and Pump stations.

Background:

There are several water treatment plants, Sewage treatment plants, and Pump stations in Jizan, a city in Saudi Arabia. Each station is operated by contractors. Feedback from the stations is not analyzed and hence maximum efficiency is not achieved. Therefore, the customer had a requirement to connect all the stations to a central control room, and control and monitoring of these stations need to be done centrally.

System Description:

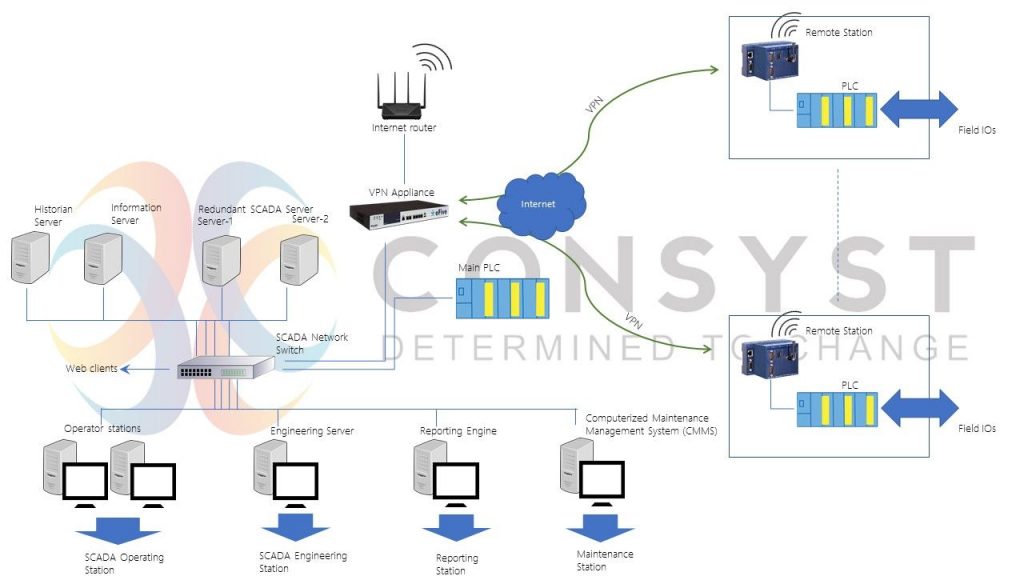

A new SCADA system is implemented to monitor all the stations. The Directorate of Water is assigned as Central Control Room (CCR). Daily production, daily data, pumping details and consumption details reaches MoEWA authorities. For this, communication is established among all the stations and centrally to CCR. Also, the supply of flowmeters and level transmitters is done at different stations.

A new SCADA system is implemented to monitor all the stations. The Directorate of Water is assigned as Central Control Room (CCR). Daily production, daily data, pumping details and consumption details reaches MoEWA authorities. For this, communication is established among all the stations and centrally to CCR. Also, the supply of flowmeters and level transmitters is done at different stations.

Implementation of a Computerized Maintenance Management System (CMMS) along with Data Analytics and Reporting Software is done. Wonderware System Platform redundant SCADA system with 100K tags is used in this project. ACTIVE, an innovative Data Analytics Software from SPIA was used for Analytics.

Data Analytics Suite

- Analyzes historical production data for informed decision-making.

- Provides management with dynamic production insight dashboards, including views by plant, zone, and other customizable parameters.

- Automatically generates reports across daily, weekly, and monthly timeframes.

- Tailored dashboards to suit the informational needs of various user levels.

Maintenance Management

- Centralized CMMS seamlessly integrated with the SCADA system.

- Comprehensive asset management for streamlined equipment oversight.

- Automated logging and scheduling for periodic maintenance activities.

- Corrective maintenance tracking with streamlined logging and scheduling tools.

- Efficient job card and work order management to optimize maintenance operations.

Through this solution, performance analysis of each station is done centrally and the customer has the advantage of reducing the manpower and improving the availability of all the stations. In Jizan, the solution helped to turn the operation of some stations into unmanned operations.